LG Chem is set to participate in a manufacturing forum in Tennessee, where it’s building the largest cathode materials plant in the United States. The company plans to emphasize the Tennessee plant’s future role as a key production hub for the U.S. electric vehicle market and will seek policy support.

LG Chem announced on Friday that it will participate in a Tennessee manufacturing forum organized by the Tennessee Chamber of Commerce & Industry.

The forum’s theme is “The Growth of Tennessee Manufacturing.” Representatives from businesses, government, and academia will attend to discuss growth strategies and the government’s role in boosting the state’s manufacturing sector.

At the event, Ko Yunju, LG Chem’s Chief Sustainability Strategy Officer (CSSO), will be the sole panelist representing a Korean company.

Ko intends to underscore how LG Chem’s Tennessee cathode materials plant will be instrumental in helping the U.S. internalize its electric vehicle battery materials supply chain and expand its market share in the future.

Ko stated, “To bolster the supply chain for cutting-edge industries like battery materials in the U.S., we need federal government incentives and policy backing to attract foreign investment.” He added, “If Tennessee’s robust manufacturing infrastructure aligns with government support, it will further accelerate LG Chem’s innovations in the U.S. market.”

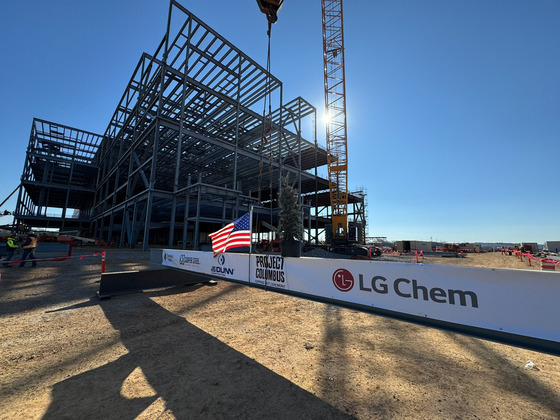

In the initial phase, LG Chem is investing about 2 trillion KRW (approximately 1.4 billion USD) to construct a cathode materials plant with an annual capacity of 60,000 tons on a 1.7-million-square-meter site in Clarksville, Tennessee. The facility is slated to begin operations in 2026.

It is expected to become the largest cathode materials plant in the U.S., with the capacity to produce materials for approximately 600,000 high-performance battery electric vehicles annually.